Canal Improvement Project

Project Description

Located in Singapore, this canal helps the city mitigate floods during stormy weather. Its banks are being expanded to increase the canal capacity, and these improvement works happen along a 1km stretch. There are three sections in this canal where metal I-beams have been deployed to hold the newly constructed canal banks together while the improvement works are happening.

According to Singapore regulations, 20% of I-beams require monitoring of load, and hence our client had installed strain gauges and loadcells on the I-beams that required monitoring. All together, they were monitoring 14 vibrating wire strain gauges and 6 vibrating wire load cells.

Problem

Since the project spans a 1km distance, and the instruments are sparsely located, cabling-based monitoring solutions become outrageously costly to deploy. So our client obtained instrument readings a few times a week using manpower and handheld readers. As the canal improvement works were progressing, the main contractor wanted more frequent readings from all the instruments, and this becomes impractical with manual readings, mainly due to the sheer distance that the team had to cover every day.

Solution

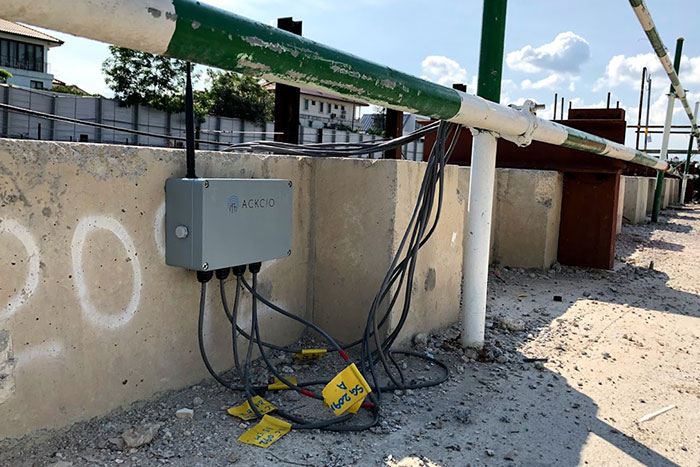

Our client installed the Ackcio Beam solution at this site to automate the monitoring process. We supplied 1 gateway and 6 units of BEAM-VW-S8 nodes for this project. The nodes were mounted near the I-beams and the load cells and strain gauges were wired to them. The gateway was placed near the site office and powered using a solar panel and rechargeable battery. They used Ackcio Cloud, our cloud-hosted data management software, to process, analyze, and report the instrument readings.

Results:

Super-quick deployment configuration:Our client’s installation team managed to set up the entire system within hours, and the Ackcio Beam smartphone app helped ease the configuration process significantly. The app allowed them to assign names to each and every node and sensor, check instrument readings, check whether the nodes were able to reach the gateway, and sync all these settings with the Ackcio Cloud to make data management a breeze.

Accurate and reliable data:The nodes were configured to send instrument data every 15 minutes, and the nodes delivered accurate readings of both the vibrating wire strain gauges and load cells.

Real-time Alerts and Reports:Our client used the Ackcio Cloud dashboard to manage the instrument readings obtained by the nodes. It helped them automate many of the manual steps they had to deal with when the readings were obtained manually earlier.

Costs and ROI:Our client’s cost in obtaining the Ackcio Beam solution for this project was 50% cheaper when compared to cabling solutions, and 70% cheaper when compared to deploying manpower to obtain manual readings.